The introduction of 3D printing has been a significant boost to the printing sector. It has revolutionized product development and manufacture since it combines multiple layers of material until it creates a 3D print model. Currently, it is a popular choice for many manufacturers following its benefits compared to traditional manufacturing and production.

The upsides of 3D printing

Affordability

3D involves only one-step manufacturing process hence saving you from other costs associated when using more than one manufacturing process alongside machines. The printers do not require supervision to work since they are programmed; hence you do not need to monitor the manufacturing process. Moreover, 3D printing can save the cost of material as it has little or no material wastage.

Accessibility

3D printing has become popular recently, following its increased availability. Locating a 3D printer is easy, especially 3d printer for business. Its easy access and low cost have accompanied its popularity. Companies like Konica Minolta sells these kind of printers.

Environmental Friendly

3D technology reduces the level of waste materials in the manufacturing and production process. 3D is lightweight; hence 3D printed models are environmentally friendly.

Lightweight and Sturdy Parts

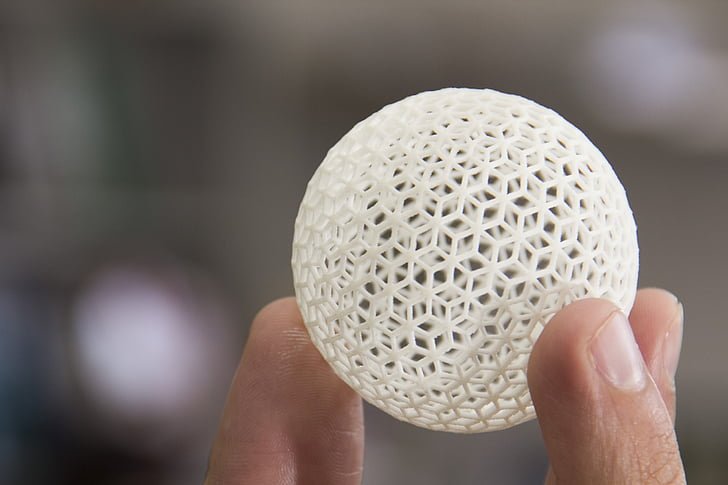

3D printing uses plastics as the primary material for printing though it can also use metals. The technology allows the production of organic and sophisticated shapes. 3D is vital in the automotive and aerospace industry since it is lightweight; it improves fuel efficiency.

Creation of Prototypes

Through the use of 3D printing technology, you can create various prototypes within a short time. The design process involved is faster and convenient, implying you can create many prototypes within a few hours.

Consistency and Quality

Using 3D printing technology guarantees quality as compared to traditional manufacturing methods. 3D printing uses a single step by step manufacturing process to ensure quality products and designs. Additionally, 3D printing has improved consistency in manufacturing and production hence reducing production time.

The Downsides of 3D Printing

Limited Material

3D technology uses plastics as the primary material for manufacturing and production. This is because plastics can melt down quickly to form layers for making the final product. However, 3D printing using metal is being adopted, but it is relatively expensive compared to plastics.

Expensive

3D printing equipment is costly; hence cannot be easily acquired for small scale use. Additionally, the materials used in 3D printing are relatively expensive compared to traditional methods.

Restrictions on the Build Size

The chamber of the 3D printing equipment is small hence restricting the part size printed. The implication here is that large items require assembling after being printed separately. This indicates that the time needed for production increases since more time is needed to join the parts manually to make the final product.

Additive Manufacturing

3D printing is one layer after another manufacturing equipment. In this case, the implication is that whereas the layers are held together, they can easily split when subjected to loads at particular stresses.